What is Pulp and how is it made?

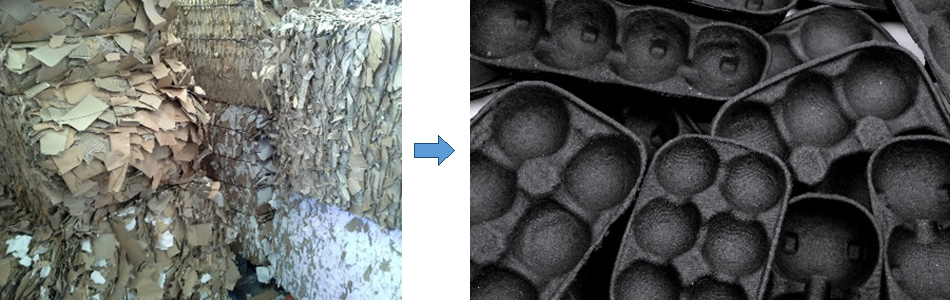

Moulded pulp is the end product when you combine recycled paper and water. The paper can come from a variety of sources including recycled newspapers, corrugated cardboard and other paper grades.

The waste paper is mixed in what effectively is a big blender with water, in a ratio of 4 parts paper to 96 parts water to get a slurry consistency, this is then moved into storage tanks where the consistency is now about 2 parts paper to 98 parts water. When the slurry is being using in the moulding process the final mix is about 1.5 parts paper to 98.5 parts water.

The water is recycled back into the process, so in a day of producing pulp about 1,000 litres of water is used, which is only 10 baths worth!

The forming moulds for the pulp form are submerged and the slurry sucked into the mould, the excess water is removed through holes in the form leaving the fibre behind, the moulds move to round so the wet press mould can form the outside of the pulp. The transfer mould removes the pulp shape from the forming mould and places it on a drying belt for drying. After about 7 minutes at 240°C the pulp is fully dry and ready for packing.

Have a look at the videos below that show our warehouse and production of the pulp.